FEMTO Engineering develops and offers skills in femtosecond laser machiningin the form of:

- Drafting specifications

- Feasibility studies

- Bibliographic studies

- Realization of prototypes

- Industrial transfer and training on site

Femtosecond laser machining allows to structure any type of material on the surface and / or in depth with a unique surface finish quality.

FEMTO Engineering performs laser machining and surface treatment:

-

- in Gaussian beam, Bessel and many other beam shaping

- in pico and femtosecond regimes

Our 8-axis machine composed of 5 high precision translation stages, 2D galvanometric scanner and a nanometric axis allow us to meet your various, complex and original needs.

- 3D and cylindrical machining and cutting

- 3D texturing

- Combination of micronic displacement precision using translation stages and ultra-fast laser processing by scanner

- Laser treatment can be performed on parts up to several tens of centimeters

Technological advantages:

- A relevant technology to machine different materials

- A contactless, athermal and non-polluting process

- A monolithic process

Our expertise

High quality micro and nano drilling

Drilling holes with high quality in different materials is readily achievable using utra-short pluses laser. Holes from several microns to

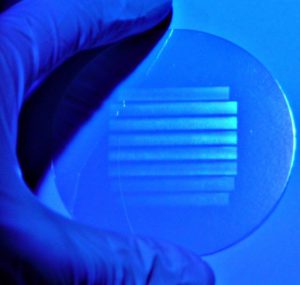

Texturing of surfaces

Surface texturing with ultra-short pulse lasers is an innovative technology that allows to apply different textures and predefined patterns of

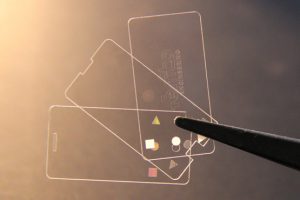

High precision engraving and cutting

The femtosecond laser allows to cut different kinds of material up to3mm thick, and to engrave various patterns in depth

High speed cutting of glasses and transparent materials

Beam shaping allows precise spatial optimization of the laser energy deposited on the material to be machined. All the energy

Equipment

Femtosecond laser

Picosecond laser

5 axis machine

Scanners

Optics and beam shaping components

Contact us

Jassem SAFIOUI, PhD

Optical Engineer

Femtosecond Laser Micromachining

FEMTO Engineering

Bâtiment TEMIS

15B avenue des Montboucons F-25030 BESANÇON cedex

- Tél +33 (0)3 63 08 23 89

- jassem.safioui@femto-engineering.fr

Lazer News

JNTE 2022, from november 28 to december 2, Besançon