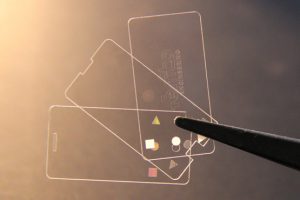

Drilling holes with high quality in different materials is readily achievable using utra-short pluses laser. Holes from several microns to several millimeters can be drilled in ceramics, polymers or metals up to 1mm thick.

A new effective and reliable technology based on beam shaping, allows to drill micron, submicron and nanometric holes in less than 1ms, hence millions of holes could be drilled in few minutes.

Hybrid holes using laser treatment + chemical or mechanical machining in also developed in our center.